Exploring Moldex3D Software Features for IC Packages: Revolutionizing Electronics Manufacturing

n the world of electronics manufacturing, integrated circuit (IC) packages play a pivotal role in ensuring the functionality and reliability of electronic devices. As IC packages become increasingly complex, the need for advanced simulation and analysis tools grows. Moldex3D, a leading software solution in the realm of injection molding simulation, offers powerful features specifically designed to tackle the challenges associated with IC package design and manufacturing. In this blog, we’ll delve into how Moldex3D can optimize IC package development and highlight the key features that make it an indispensable tool for electronics engineers.

1. Comprehensive 3D Simulation

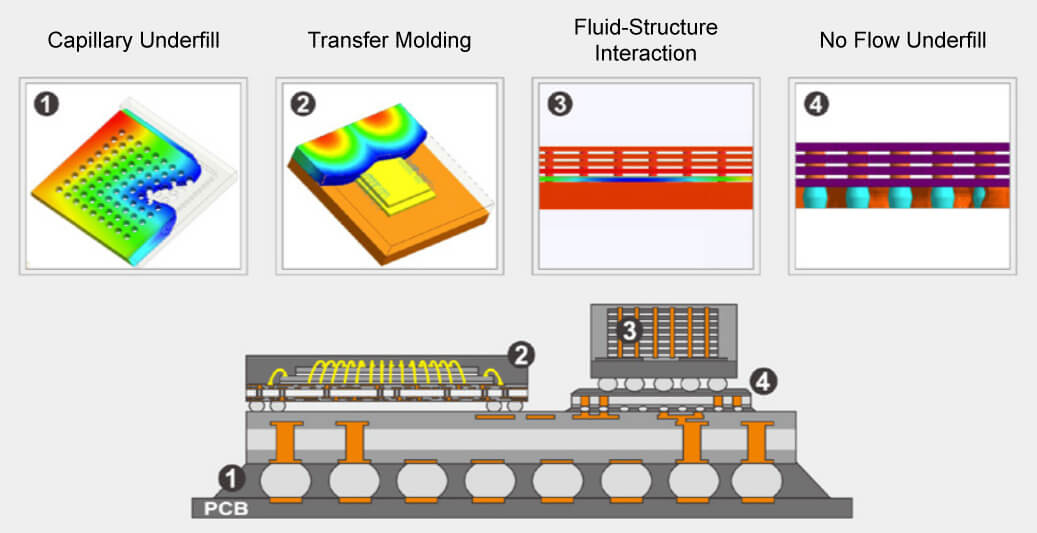

Detailed Geometry Representation: Moldex3D provides advanced 3D simulation capabilities that accurately represent the complex geometries of IC packages. This includes detailed analysis of package structures, including lead frames, mold cavities, and encapsulation layers. By visualizing the complete geometry, engineers can better understand how different design elements interact and identify potential issues before physical production.

Realistic Material Behavior: The software simulates the behavior of various materials used in IC packaging, such as epoxy resins and fillers. This helps engineers predict how materials will flow, cool, and solidify during the molding process, enabling them to optimize material selection and process parameters for better performance and reliability.

2. Advanced Flow Analysis

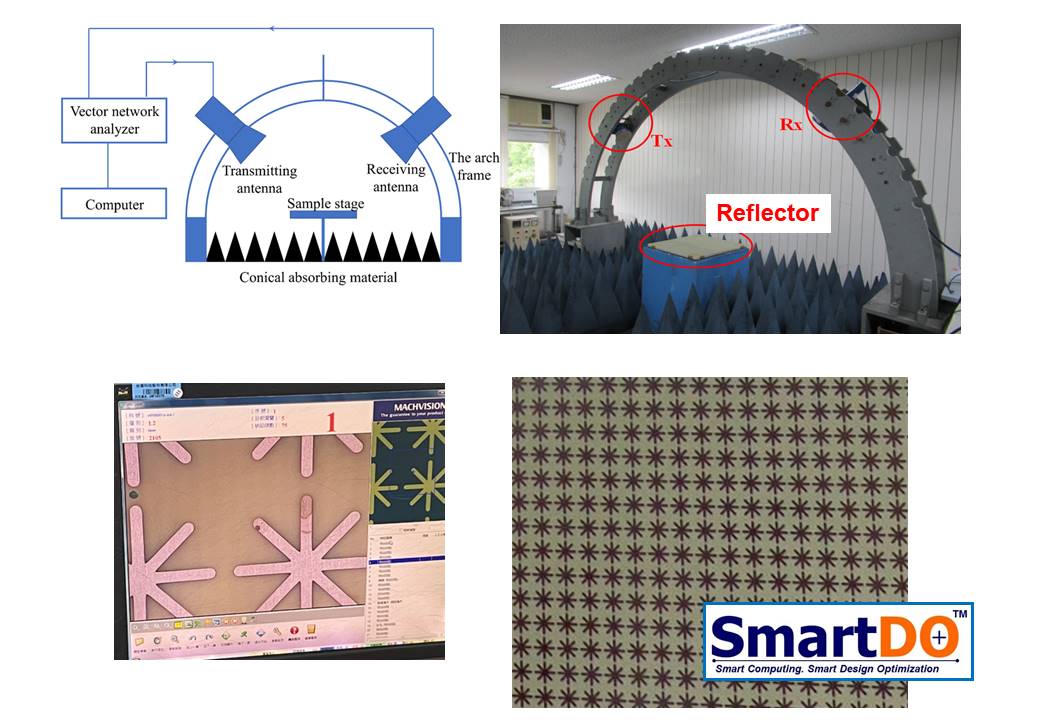

Injection Flow Simulation: Moldex3D excels in simulating the injection molding process, providing detailed insights into how molten material flows through the mold. For IC packages, this includes analyzing the filling patterns, gate locations, and potential air traps. Understanding these factors is crucial for ensuring complete filling and avoiding defects such as voids or incomplete encapsulation.

Warpage Prediction: Warpage is a common issue in IC package manufacturing due to uneven cooling and differential shrinkage. Moldex3D offers precise warpage prediction tools that allow engineers to anticipate and address potential warping issues. By simulating different cooling strategies and material choices, users can minimize warpage and enhance the dimensional stability of IC packages.

3. Thermal and Mechanical Analysis

Thermal Analysis: IC packages are subject to significant thermal stresses during operation. Moldex3D includes advanced thermal analysis capabilities that help engineers understand how heat is distributed and dissipated within the package. This information is vital for designing effective thermal management solutions and ensuring the long-term reliability of the IC package.

Mechanical Stress Analysis: The software also provides mechanical stress analysis to evaluate the impact of stresses on the IC package. This includes assessing stress concentrations around leads, bond wires, and other critical areas. By identifying potential stress-related issues early in the design phase, engineers can make necessary adjustments to improve the mechanical robustness of the package.

4. Process Optimization

Design of Experiments (DOE): Moldex3D incorporates Design of Experiments methodologies to systematically evaluate the effects of various process parameters on IC package performance. By running multiple simulations with different parameter settings, engineers can identify the optimal conditions for achieving the desired quality and performance.

Optimization Algorithms: The software features optimization algorithms that automatically adjust process parameters to achieve the best results. This includes optimizing injection speed, temperature settings, and cooling rates. By leveraging these tools, manufacturers can enhance efficiency, reduce cycle times, and minimize defects.

5. Integration and Collaboration

Seamless Integration: Moldex3D integrates with popular CAD tools, allowing for smooth data exchange between design and simulation phases. This integration ensures that engineers can easily import and analyze complex IC package designs without manual data conversion.

Collaborative Tools: The software supports collaborative workflows, enabling teams to work together on simulation projects. Shared access to simulation results and insights fosters better communication and coordination, leading to more effective problem-solving and decision-making.

6. User-Friendly Interface

Intuitive User Experience: Moldex3D is known for its user-friendly interface, which simplifies the setup and execution of simulations. With easy-to-navigate menus and visualization tools, engineers can quickly set up simulations, interpret results, and make informed design decisions.

Comprehensive Documentation: The software provides extensive documentation and tutorials to help users get the most out of its features. From detailed user guides to instructional videos, Moldex3D ensures that engineers have the resources they need to effectively leverage its capabilities.

Conclusion

Moldex3D offers a robust suite of features tailored for the complexities of IC package design and manufacturing. From comprehensive 3D simulation and advanced flow analysis to thermal and mechanical stress analysis, the software provides the tools needed to tackle the unique challenges of IC packaging. By incorporating Moldex3D into your design and manufacturing processes, you can enhance the performance, reliability, and efficiency of your IC packages, ultimately driving innovation in the electronics industry.

Whether you’re an experienced engineer or new to the field, Moldex3D’s powerful capabilities and user-friendly interface make it an essential tool for mastering the intricacies of IC package development. Explore the possibilities and see how Moldex3D can revolutionize your approach to electronics manufacturing.