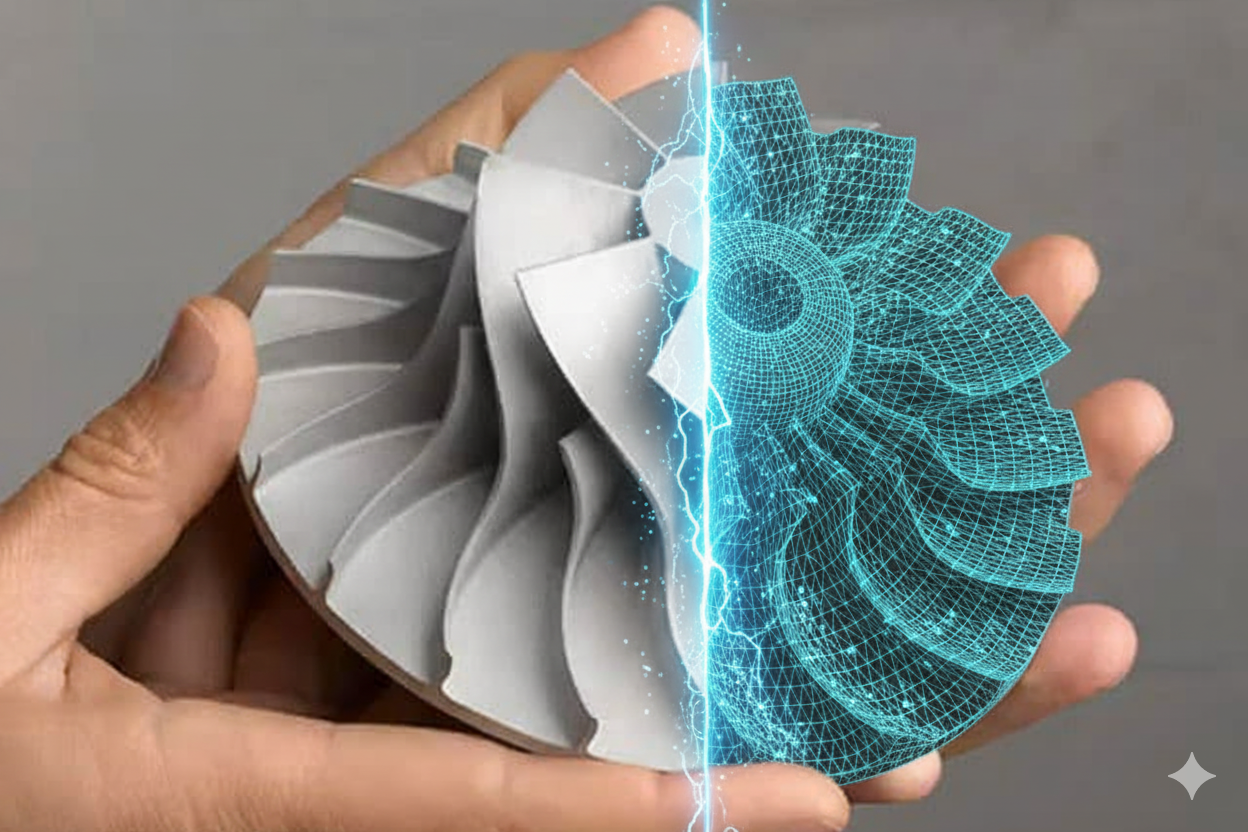

Our consultants cover end-to-end "How to design and develop a product from a concept to manufacturing process" and help you make prototypes (models) of your custom products.

Our 3D printing technical consultancy services are very effective in a variety of industries, such as commercial products, industrial products, aerospace products, healthcare products and many other sectors. .

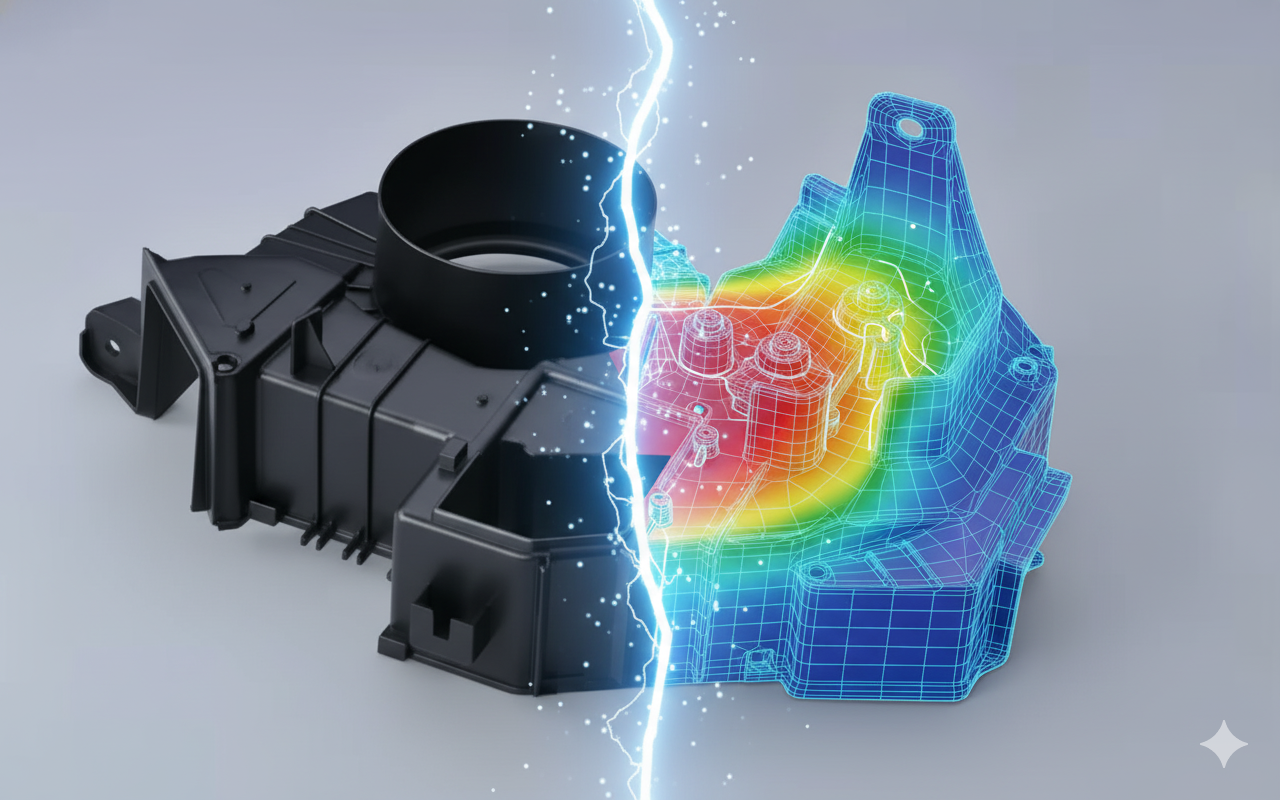

We have specialized in consultancy in the design of plastic and rubber molds for many years. Our mold consulting has experts who have worked with both Engineering and commodity plastics.

Vacuum casting is one of the most cost-effective ways to produce high quality, low volume plastic parts which can be like injection molding parts. Functional prototypes and Pre-production samples for Marketing or display models.

Be indigenous design thinking & Through iterative examples of understand,synthesis, make and test

conducive to more effective solutions.

Driven by plan attitude & Be confident that it works

Endeavouring to consider rich and inventive game plans & Eliminate cost in every area.

Does any industry experience a more intricate audience journey and sales and marketing process than B2B technology?